BS EPG

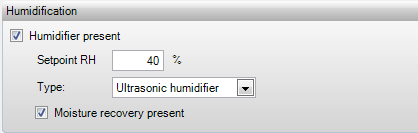

This box allows

you to indicate whether a humidifier/dehumidifier is present and should be taken

into account in the calculations. The specifications of the dehumidifier can be

indicated in this screen. The effectiveness of the coil is determined based on

the thermal power delivered at a given water supply temperature, air supply

temperature, and moisture conditions. The software is able to determine the

maximum thermal power under various conditions (air volumes, supply

temperatures, moisture content, etc). The true air volumes (in the given

conditions) are specified from the supply fan, and the supply temperatures from

the heating curves for water and air. The cooler/ dehumidifier is controlled

based on temperature and moisture content.

[%

RH] BS

The setpoint determines when the system must

humidify/dehumidify the air. This part is activated when the relative humidity

is below the setpoint for humidification and above the setpoint for

dehumidification. The moisture conditions are important as these determine the

effectiveness of the cooling coil for a large part in case of

dehumidification.

|

BS |

ISSO Publication 32 (2011), Section 5.3 Design Criteria for humidity

|

EPG

The type of

humidifier is only applicable for EPG calculations (Source: SenterNovem).

If the selected type is the electricity-driven steam vaporizer, then the energy

source will be electricity in the EPG calculation. For the other types, the

required energy is provided by the heating system and whatever generator is

specified for.

•Gas-driven steam vaporizer. Steam is blown into the air through a tube with holes. The steam is generated in one or more small gas boilers by the evaporation of water. These devices heat up water using a heating element driven by gas. The obtained vapour is added to the air in a controlled way.

•Electricity-driven steam vaporizer. Steam is blown into the air through a tube with holes. The steam is generated in one or more small electric boilers by the evaporation of water. These devices heat up water using a heating element driven by electricity. The obtained vapour is added to the air in a controlled way.

•Ultrasonic humidifier. In this method, water is atomized by means of ultrasonic vibrations in aerosols. The air in the channel in which these vibrations take place absorbs these aerosols quickly. The movement of air is achieved using a ventilator. The relative humidity can be kept at a high level with this method.

•Adiabatic humidifier. The humidifier works through the expansion and contraction of air; literally adiabatic means: without heat exchange with the environment. So no heat exchange occurs in an adiabatic process, but rather compression leads to heating and expansion to cooling.

[%] BS

The setpoint determines when the system must

humidify/dehumidify the air. This part is activated when the relative humidity

is below the setpoint for humidification and above the setpoint for

dehumidification. The moisture conditions are important as these determine the

effectiveness of the cooling coil for a large part in case of

dehumidification.

EPG

In this box it can be

indicated if moisture recovery is present. If this is the case, a reduction to

the energy need for humidification is surcharged.

|

|

NEN 7120, Section 18.2 |